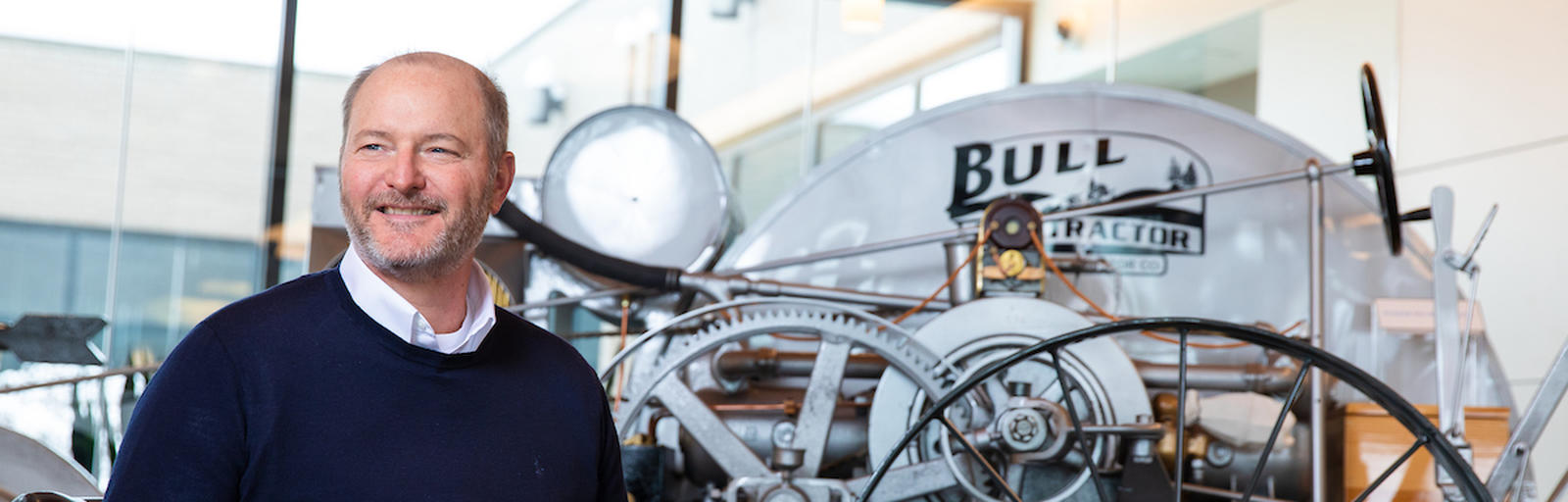

Donaldson Company CEO Tod Carpenter Makes Big Impact With Little Fuss

Thursday, April 18, 2019

Tod Carpenter, '99 MEP, knows how to think big—and small. As the chairman, president and CEO of Twin Cities–based Donaldson Company, he oversees the development of filters that are used around the globe in nearly every industry imaginable. Some, the size of a fingernail, protect computer data. Others, as big as a house, keep power grids running.

For more than 100 years, Donaldson filters have been doing everything from protecting workers from harmful fumes and keeping dust out of the air in your home to reclaiming gold dust for Tiffany and filtering the water used by Coca-Cola.

Carpenter, who has been with the company for 23 years, picked up the baton of leadership in 2014. Like his Donaldson predecessors, Carpenter is a big supporter of the Carlson School and a member of the school’s Board of Advisors.

“Serving on the board is important to me because education changed my life’s path,” he says. “I am passionate about giving back to education and helping students.”

He sat down with us to talk about his business, his background, and why he loves living in the Twin Cities.

When people think of filtration, they probably think of household filters. But your company works on much larger and smaller scales. Tell us about some of your most interesting products and what they do.

Donaldson’s filtration products and technologies aren’t always visible, but they are used in hundreds of ways, every day. And they are found nearly everywhere—places we live, work and play—in bulldozers and trucks; helicopters and airplanes; water bottling plants and gas turbines; and car headlights, cranes, and computers.

One example is helping manufacture the food we eat, like yogurt. Current yogurt production, filling, and packaging lines require a high degree of cleanliness and sterility. When you open the lid of a yogurt container you will find a gap between the yogurt and the lid. That is where we come in: Donaldson’s food and beverage filters provide sterilized air between the yogurt and the container’s lid.

Another example is fuel. Imagine a tractor idling in a dusty field where the farmer harvests his crop. As fuel is injected into the tractor’s engine cylinders under extremely high pressure, the dusty conditions can cause system damage when microscopic contaminants get in the fuel. Donaldson’s state-of-the-art fuel filtration helps customers fuel injectors to continue to work efficiently for longer periods of time which in turn keeps the engine protected.

How did you wind up at Donaldson?

My career at Donaldson started with a desire to move back to the Midwest—my wife and I decided on where we wanted to build our life and then built careers around that goal.

In 1994, after 13 years with Hughes Aircraft in California, I took a job as an IT and managerial consultant in the Twin

Cities. It was in this capacity that I was introduced to Donaldson, working first with Donaldson’s Gas Turbine Systems (GTS) group and later with information technology for the engine group. In 1996, I joined Donaldson as director of GTS operations.

What’s the most important issue facing your industry?

Talent. It is difficult to find enough skilled workers. Our corporate headquarters, which employs over 1,100 people, is in Bloomington, Minnesota, where statewide unemployment is 2.8 percent. We also have more than 60 manufacturing plants, distribution centers, and third-party logistics services, and more than 100 sales offices, and we continue to grow and expand. Finding talented people, from PhD scientists to supply chain personnel and manufacturing assemblers to global sales managers, will continue to be a big challenge.

What’s your proudest achievement at Donaldson so far?

To date, I would say it is a focused and concerted effort on development. We have built a strong leadership team and continue to invest in their development. We know that having the right people in the right roles is critical to our success. And when people are better aligned, the company is stronger. Over the last three years, we have rolled out our One Donaldson Leadership Expectations framework, which represents the competencies and behaviors that have made us a great company for more than 100 years and provides the basis for what we aspire to for our continued growth and success. The competencies are designed to continually challenge one’s growth and development.

You studied industrial engineering. What did you like about it?

I have always been fascinated by the entire manufacturing environment and seeing how things are made, no matter what they are.

You came from a big family. Tell us about your childhood. What was your favorite thing to do?

I was number eight of 10 children, and growing up, one of the best things I remember were the holidays. It was one of the occasions when the majority of us were together. I learned to work hard from my father and it was my mother who always stressed the importance of investing in yourself and your education.

What was your first job?

In the 1960s, I was flipping hamburgers at Art’s Drive-In.

When did you know you wanted to go into the industrial engineering field?

During my sophomore year in college, I read a lot of books, reviewed syllabi, and talked with upper classmates to understand the different majors within the school of technology and the school of business. The curriculum for industrial engineering attracted me the most; I especially liked the hands-on learning aspect of the curriculum—that was really the selling point for me.

What brought you to the Carlson School?

My experience with the Minnesota Executive Program (MEP).

Why is serving on the Carlson School Board of Advisors important to you?

The University of Minnesota is very important to our future. As a 104-year-old local company, Donaldson has counted on and continues to count on the U to build our bench of future Donaldson leaders and to partner with us for scientific research on filtration. Currently, about 16 percent, or nearly 200 people, of our headquarters’ population has graduated from the U, with about two-thirds having bachelor’s degrees and the balance having a variety of degrees, including MBAs and PhDs.

What makes the Twin Cities special?

I think Minnesota is just fantastic. Any curiosity you have—it’s all here. The diversity of the Twin Cities area allows you to pursue your interests. I’ve lived in multiple states and multiple countries in my life, but we have lived the longest in the Twin Cities. My wife, Bonnie, and I chose to move here because of the great education system and public amenities, and it’s a great place to raise a family. It has not let us down.

What’s your best piece of advice to today’s Carlson students?

Always invest in yourself. It helps build a strong foundation so that you continue to grow and achieve your dreams.